Industry 4.0

NGS grazie alla collaborazione con una importante azienda leader nella produzione e trasporto di energia elettrica ha sviluppato una soluzione completa per la Predictive Maintenance through the monitoring and control of medium-small sized electric machineries, called PlantOne. NGS has therefore created a complex network of sensors (i.e., vibration, contact temperature, pressure, gas), a Gateway to aggregate the data arriving from the sensors, a remote platform where the data is stored and processed, and a visualization portal to enble the monitoring of the machineries health status . The IoT components by NGS are thought to be easy to use and install, and are perfect for retrofitting. The Gateway was developed with the aim of being as flexible as possible and therefore using different transmission protocols. In this way, this Predictive Maintenance solution is thought for the SMEs' needs, thus capable to enable complex monitoring functionalities for low cost machineries, with high processing values: as for example suction systems in chemical companies.

PlantOne is a system thought for the predictive maintenance democratisation, thus easy to install and to use, thought for saving money retrofitting existing solution. Its as a service business model makes it affordable for SMEs' too.

PlantOne is designed to be not invasive (wireless and battery powered). PlantOne is based on the innovative wireless IoT technologies.

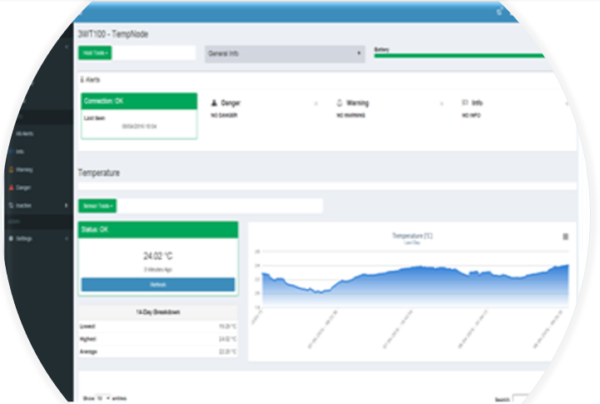

Remote data visualisation and alarm generation.

Ready for the market

How does PlantOne work?

Sensor Node

Complex IoT network to implement added value measurements regarding important parameters for predictive maintenance and industrial monitoring. Gas concentration, vibrations, contact temperature, pression, and ... low resolution termal camera

IoT Gateway

The IoT Gateway receives the data from the sensor nodes installed in the industrial premises. It aggregates the information and data received and forwards them to a Cloud platform or to a Physical Server.

Cloud

The Cloud platform or the Physical Server receive the aggregated data from the Gateway, where they are processed, stored and made available to the monitoring system. It is in charge of generating alarms too.

Monitoring interface

The monitoring interface allows the visualisation of the data available at the Cloud platform side and allows a detailed remote control of the performance of the machinery on which the sensors have been installed.

Predictive maintenance sensors (vibration and contact temperature) for monitoring secondary machineries in the Federico II Power Plant.

The IoT gateway deployed in the plant facility and capable to manage a scalable set of devices. Prototipo della G.S.F. (Kaiserlautern, Germania) Risultati di BEinCPPS OC1 Fine del progetto: fine settembre 2017 La distribuzione terminerà a metà settembre 2017

Monitoring systems capable to visualise the parameters and the event collected on the field.

The Sensor nodes

PRESSURE SENSOR

NGS

NGS

NGS

NGS

NGS